Overview

Nozzle lance assemblies are designed and manufactured to individual customer requirements.

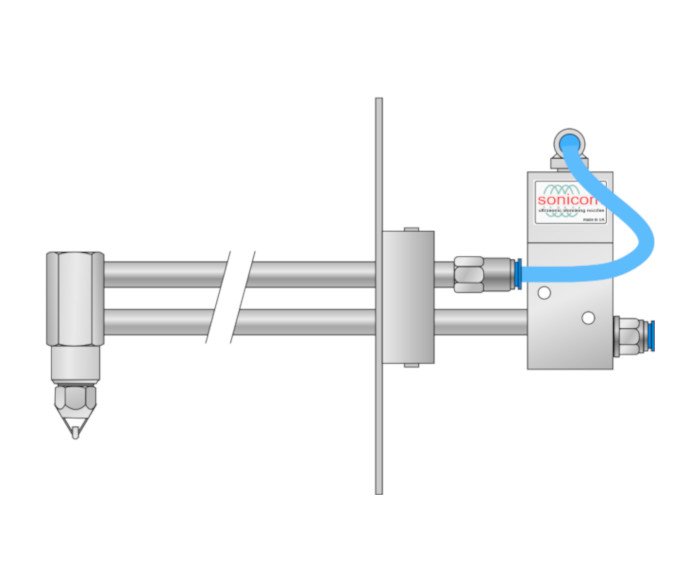

Each ultrasonic nozzle is mounted on an adjustable flange assembly specifically made to suit the desired central position within a duct, curing oven or similar chamber. The lance can be supplied with or without a liquid valve which, on a single nozzle lance, provides a non-drip operation at the end of each spraying cycle.

A standard 150mm square flange with four Ø10mm holes at each corner provides a substantial fixing to the outside of the ductwork. This leaves the valve, air and liquid connections exposed for easy assembly and maintenance and away from any contaminates within the duct.

Custom built lances can be manufactured to adapt specifically to unique installations including curved flanges, larger mounting holes, etc. A 90° assembly is also available to project the nozzle tip forward into the duct ahead of the entrance point.

Wherever possible stainless steel parts are used to avoid corrosion and contamination within the air stream and each assembly can be colour coded for identification purposes if required.